The universe is made of energy, frequency, and vibration. Electricity is the Qi of life flowing through humans, birds, and circuits alike. My new "Analog Electronic Crow" (2022) is an evolution of Deep Fake Birdsong from 2020 in which I explore the power of electrically oscillating circuits to manifest intelligent behaviors. This circuit has only six oscillators: five astable multivibrators and one modified Hartley. It's battery operated so you can carry it around. Stay tuned for a product launch this Fall!

design

Birds in various cages, Faraday etc. /

Screenshot from a work in progress. Birds in various cages, Faraday or otherwise. September 2019

Detail of new work in progress /

Detail of new work in progress, 2019

Pretty Bird gets Bigger /

A to-scale inkjet print of my latest (and considerably larger) pretty bird circuit. Kelly Heaton, July 2019

My Pretty Bird circuit is about to fly to China and get bigger.

Moth bus /

I've been making moth trails in the form of animated light. To learn more, please follow the links below.

https://hackaday.io/…/163201-electronic…/log/161522-moth-bus

Designing creatures of the night /

Cricket Circuit /

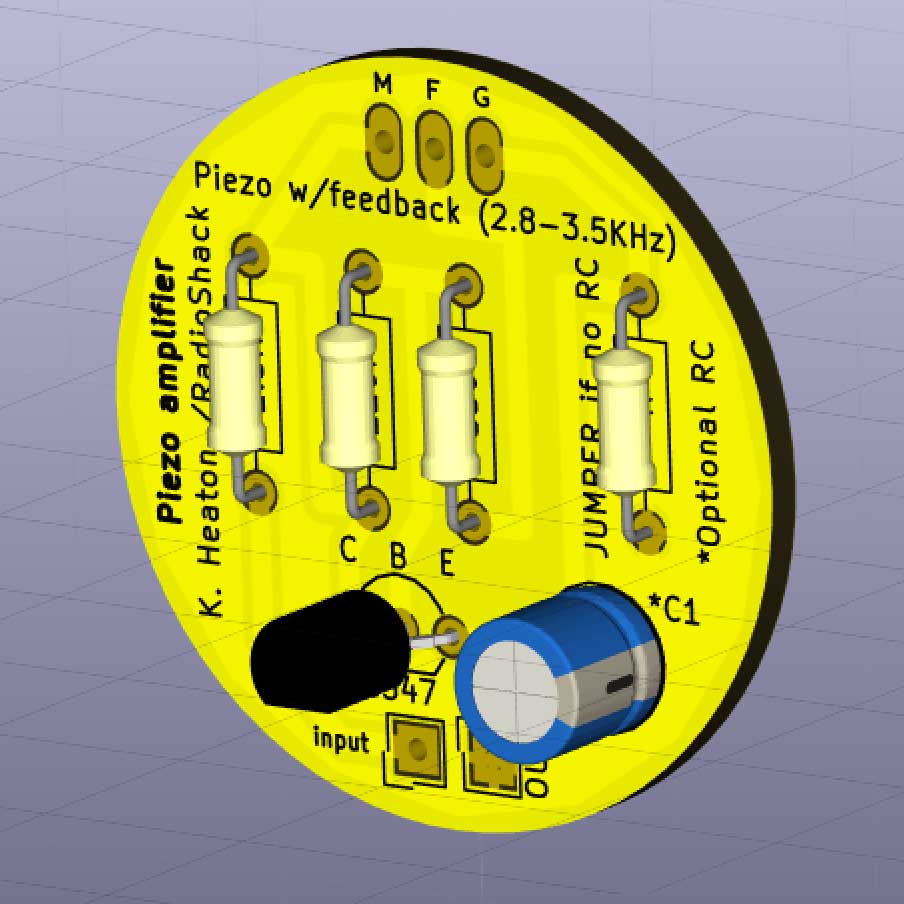

The chirping piezo electric circuit from my last post is getting a body. I did the layout in KiCad and sent my boards for manufacture by PCBWay (based on a colleague's recommendation). Their interface is not as user-friendly as OSH Park, but they offer a variety of solder mask colors - not just purple. I ordered this guy in black. I'll post an update when the boards are wired up and chirping.

Board layout in KiCad

KiCad 3d simulation of the pcb

Piezo acoustics /

This will be one in a series of blog entries about engineering, as I am building a new "electrolier" sculpture from scratch.

Sometimes, art requires that I push myself into the non-linear intelligence of my right brain, what Carlos Castenada refers to as the nagual - a consciousness distinct from reason that is non-verbal and non-analytical. Other times, art requires that I focus on the tonal, or my capacity for reason and logic. Engineering is an extremely tonal activity. This is my current mind-frame out of necessity.

The insect noises that I create for my art rely on a piezo electric disk element. (I will save "why" for another blog entry on the nature of sound.) I have used piezo buzzers manufactured by Radioshack for at least a decade, notably parts #273-059 and #273-060, as I find their sound character and ease-of-use to be optimal. However, these buzzers became hard to get when RadioShack went out of business a few years ago, and I was forced to find a substitute. What was initially a pain has turned out to be good fortune, as I have learned how the buzzers work, designed a less expensive solution, and discovered new opportunities to shape sound.

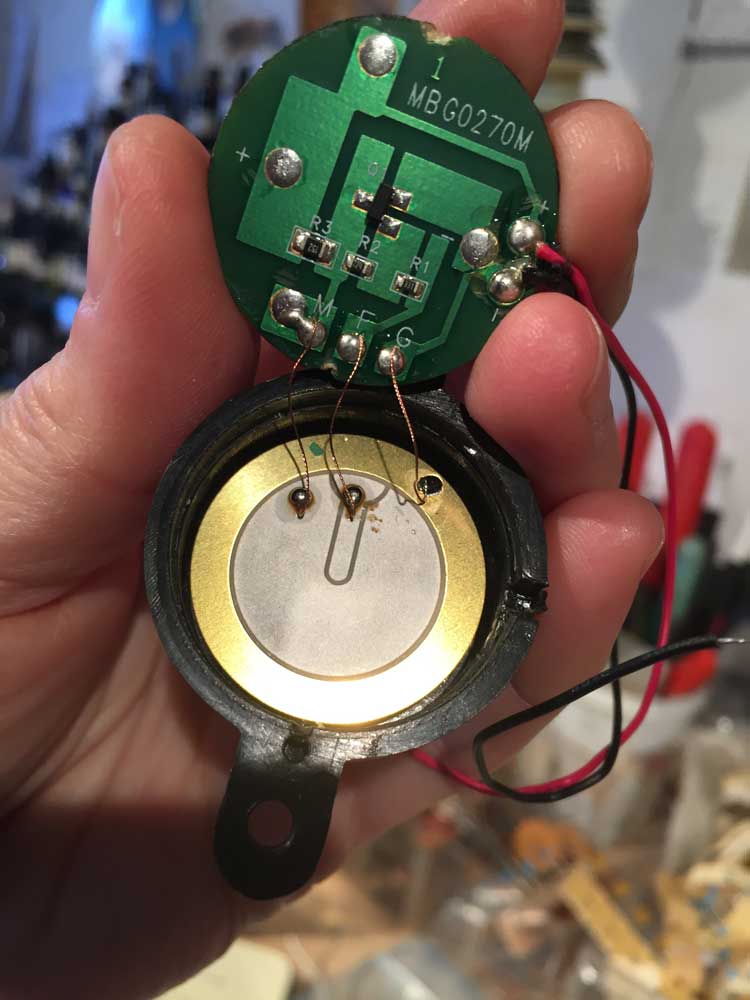

Fumble number one was my discovery that not all piezo disks are made equal. Some have two contacts and are best suited for electrical pick-up (like listening to tiny sounds). The kind used in a RadioShack buzzer is a piezo with feedback and has three contacts: M (main), F (feedback), and G (ground). "M" is sometimes associated with a red wire, "F" a blue wire, and "G" a black wire -- just in case you encounter this color-coding, but don't get confused when you look at my piezo disk below because I substituted a white wire for the "F" contact.

Piezo disk elements also have different resonances, so you need to get the right one for your sound. RadioShack buzzers are in the 2.8 - 3.6 Hz range. I bought comparable piezo elements from Digikey, like the one pictured above right: https://www.cui.com/product/resource/ceb-35fd29.pdf

The next challenge I confronted is how to drive the raw piezo element. RadioShack buzzers include an internal amplifier circuit (see below left), so I reverse engineered their design. It's a simple NPN transistor amplifier - I found that BC547 works well. Below you can see the RadioShack circuit on the left and my KiCad schematic on the right. My unspecified resistor and capacitor to ground are optional, although I almost always use a resistor to ground (like 1K). If you don't use a resistor or capacitor to ground, then you must place a jumper wire here.

On to the next step, was to lay-out my design for the printed circuit board.

The image on the left shows the board with the ground fills turned off (so you can see the traces). The two images on the right are a KiCad simulation of the actual board, which I'm having made by PCBWay in China (as of April 2, 2018).