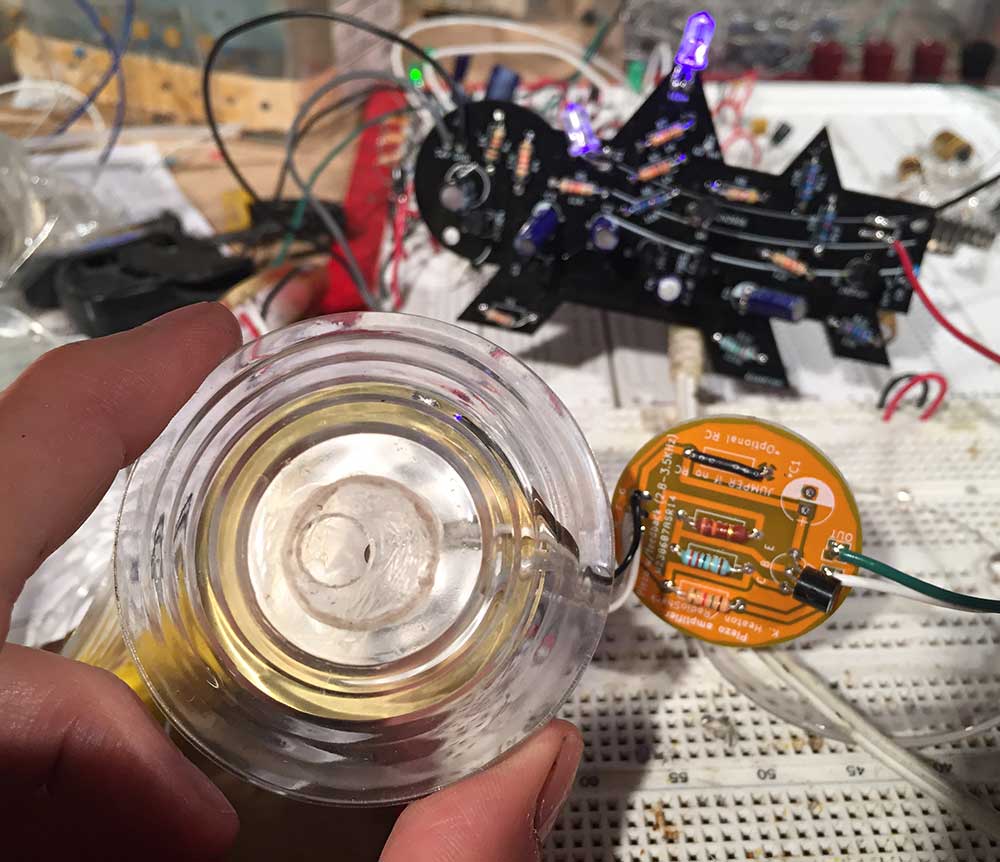

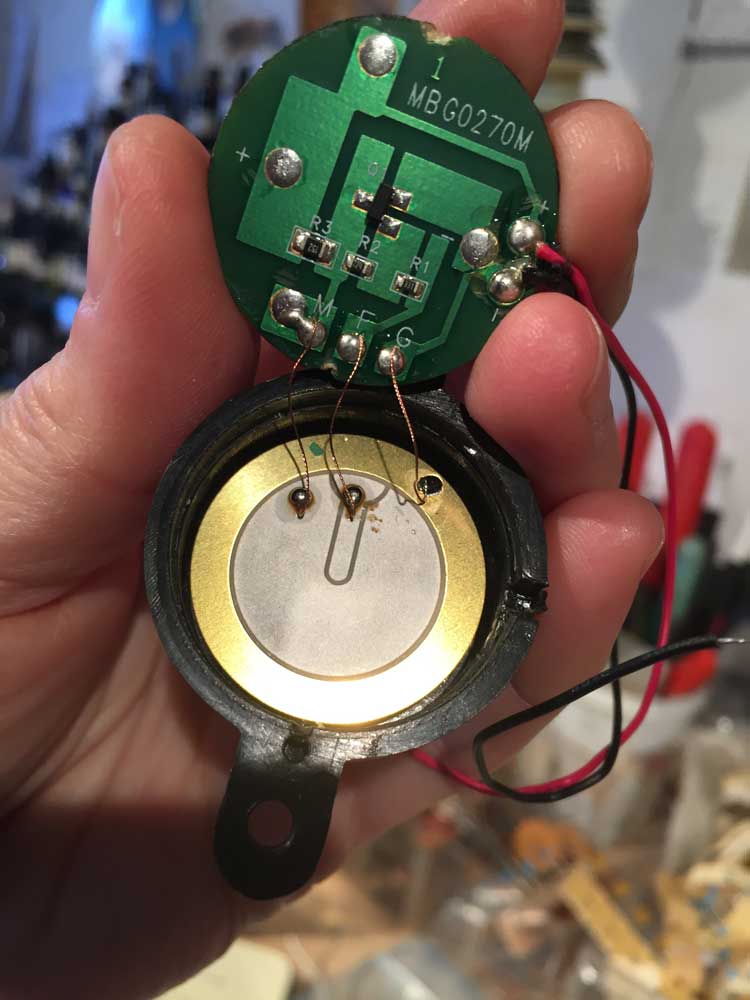

Here's a prototype of a housing for a piezo speaker that I will actuate with analog electronic insect sounds. The shape of the housing and mechanical pressure on the piezo element will change the pitch as well as the volume. I made this housing by first laser cutting 1/4" acrylic and gluing the stacked rings to make a pyramidal-shaped buck — see images below. Note that there's a central hole all the way through the buck to aid the vacuum forming process. I’ve vacuum-formed .080” and .090" acrylic sheet over the buck (both work fine) and used a laser to cut the shapes out. My registration needs improvement, but you get the idea. The piezo element is mounted inside of the housing by a short length of plastic tube that I glued in place.

Below I show my process to cast the acrylic buck in plaster (using an alginate mold). I will use plaster, wood, or metal bucks in the future because acrylic deforms in the vacuum forming process. In either case, it is critical to use mold release.

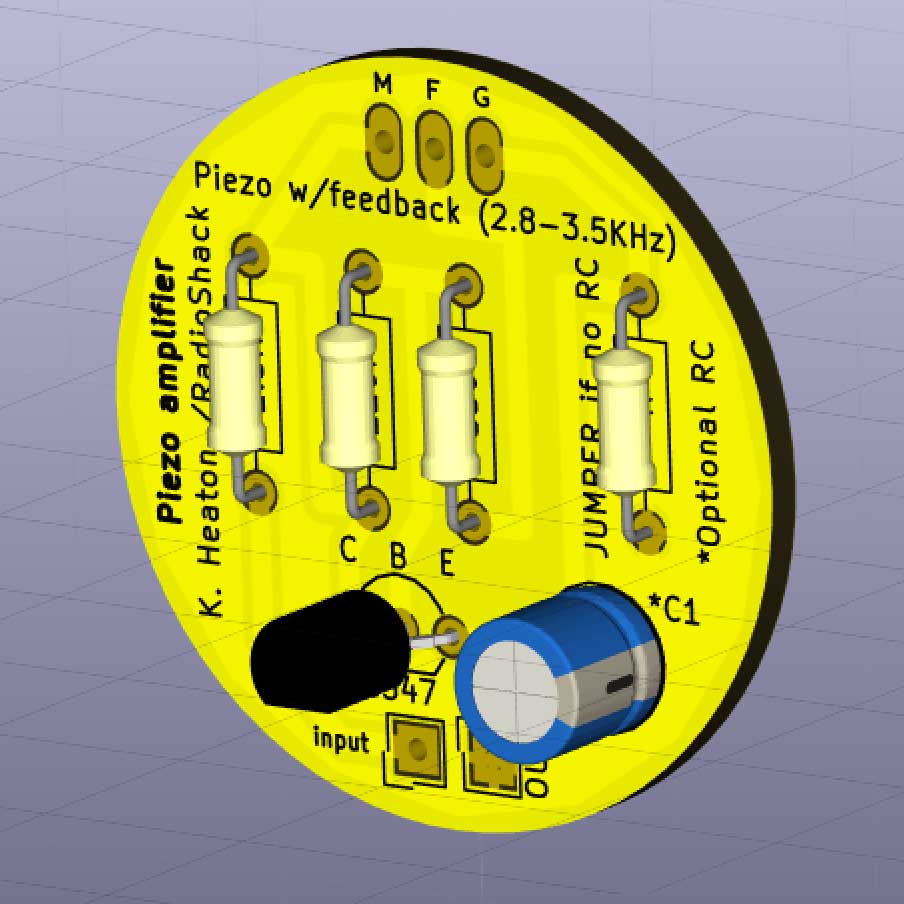

Why am I doing this? Because when RadioShack went out of business, I could no longer buy the piezo speakers that I used for my insect sounds. I was forced to reverse engineer the part --which turned out to be a blessing because the sound of insects is heavily dependent upon the mechanics of speaker design (not just the electronics which drive the speaker). For a previous blog entry on this issue, link here or read about my project “Hacking Nature’s Musicians” on Hackaday.io